详细描述

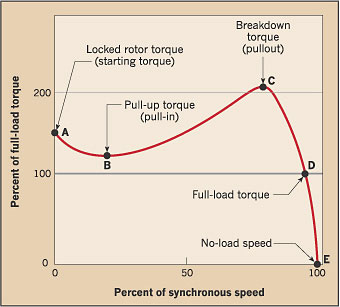

1. To avoid the breakdown point, the higher power motor is required, which we call "big house drive the little car", it is a big waste of the energy.

2. when the motor works exceed the rated operation point, the motor efficiency is reduced exponentially. Because the whole process, the time under rated operation is very short, and other points, the efficiency is limited. Consider the whole process, the total efficiency is quite low.

3. can't adjust the motor performance by various working condition ( various materials, various thickness etc)

Volcano Electric Brushless Motor solution in drilling machinery

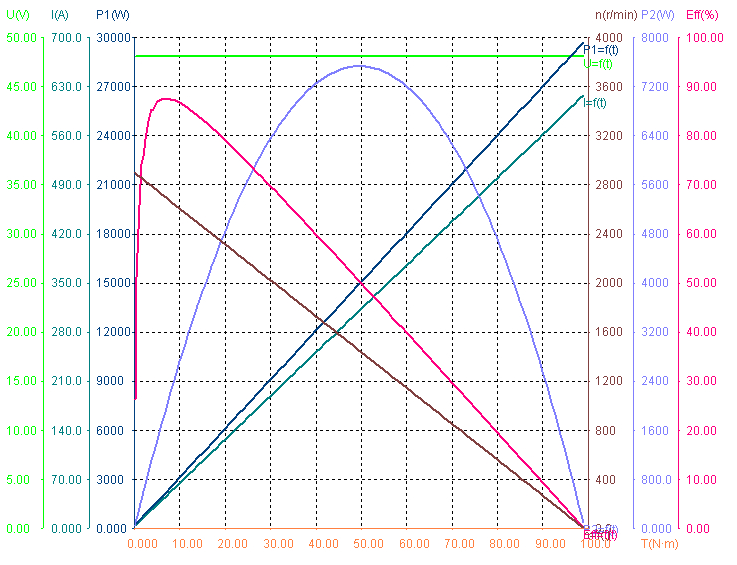

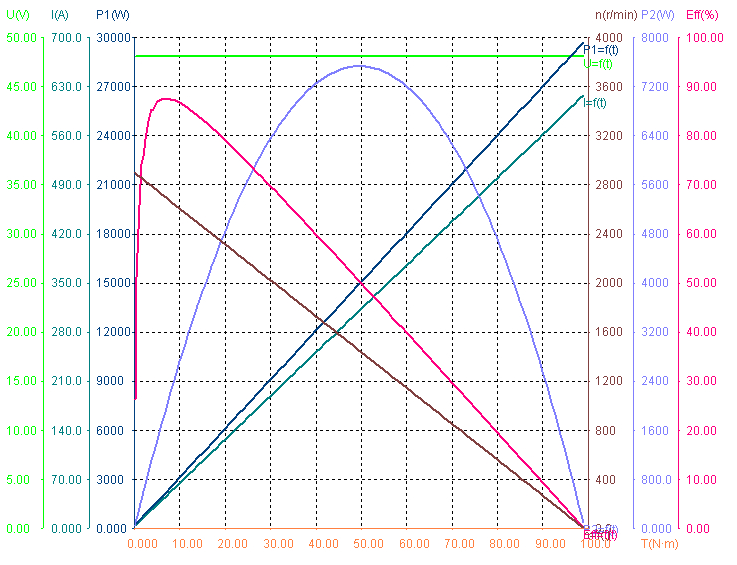

Performance chart of brushless DC motor

By the performance chart, T-N chart is straight line, torque rises up while the speed is down, there is no any breakdown point (different from asynchronous motors), thus no locked-rotor point. What's more, by controller, the motor performance can be adjusted automatically accordingly to the load changing, therefore, at various work speeds, the motor can work at high efficiency. There are some advantages of the brushless DC motors:

1. Higher efficiency

2. Compared to asynchronous motors, you can chose lower power brushless DC motors in the same working condition.

3. Motor size is smaller

4. Intelligent temperature control

Moreover, with Volcano Electric Brushless DC motors , we have more advantages like:

1. We have the technical team of up computer and controllers, in addition to the motors, we can offer one-stop service for your motor application.

2. Due to the motors and controllers offering from one company, you can avoid the risk that different suppliers shift responsibility.

3. Capability of large data management, with the large data management interface, built-in memory, Big data can be combined with the analysis of empirical data, to fulfill the self identification by various workpieces, various working speed etc, then control the speed of spindle motor or through joint interface notify rocker arm to control the feed speed. In this way , to achieve automation to intelligent leaps.

4. Strong R&D team in customized energy saving motors, our Chief Technical Operator is an Australian Engineer, who has 30-year experience in researching and designing brushless DC motors, which help customers to design proper motors in various application at high efficiency.

For professional brushless DC motor advices, please contact us at info@volcanomotor.com

Similar application of this motor solution: band saw machine, drilling machine, metal cutting machine, industrial machinery.

Keywords: motors in drilling machine, spindle motors. Brushless DC motors in drilling machine, dead point of induction motors, Locked-rotor torque