详细描述

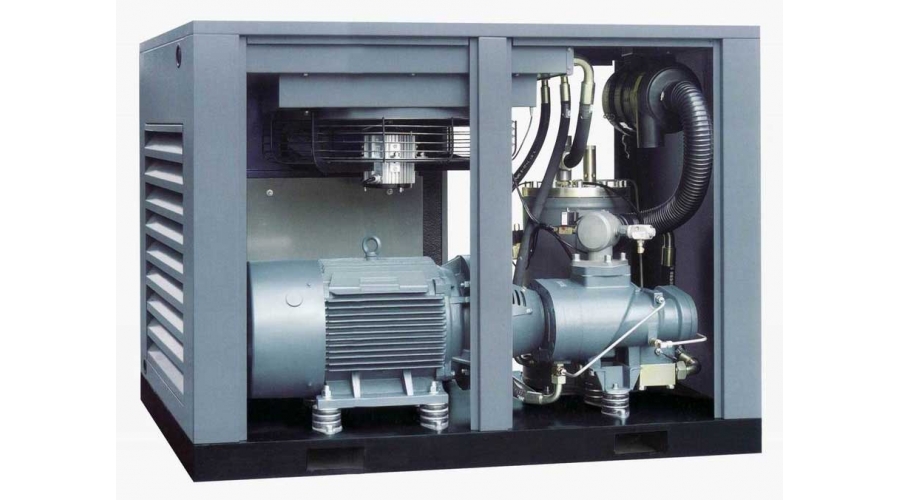

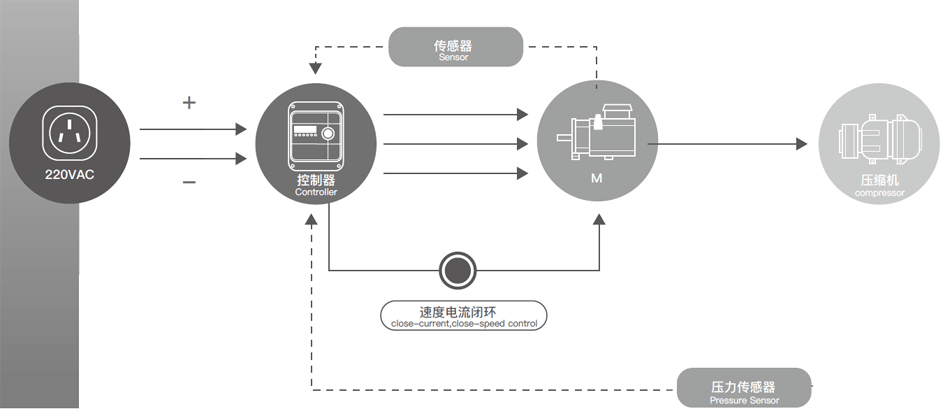

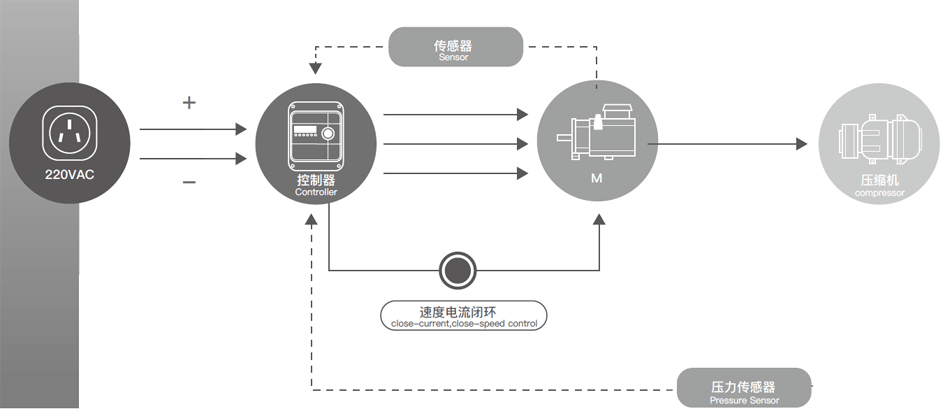

The Energy saving compressor system is composed of a control panel, motor with sensor, pressure sensor, and a compressor. The current case is 220V AC/380VAC power supplying the controller to control the motor, meanwhile the motor sensor transfers the location signal to the controller. The pressure sensor in the compressor system transmit the pressure value to the controller, based on these pressure value, the controller carries on the real-time speed control. thereby achieve the function of constant pressure of the whole compressor system.

Moreover, the controllers can be connected to the buses, the controller can control different motors, if the pressure is insufficient, the other motors would work simultaneously to keep the constant pressure.

System chart of intelligent air compressor

You can refer to the system chart, once the pressure is reduced, the motor would speed up to boost, to keep the system pressure stable. Because controllers are connected to the buses. In case, the insufficient pressure that one compressor can’t meet, the system would open the compress 2, compressor 3,… intelligently. Opposite process can work as well. All the process is automatically, by close loop control. The intelligent system can help to saving energy and keep constant pressure.

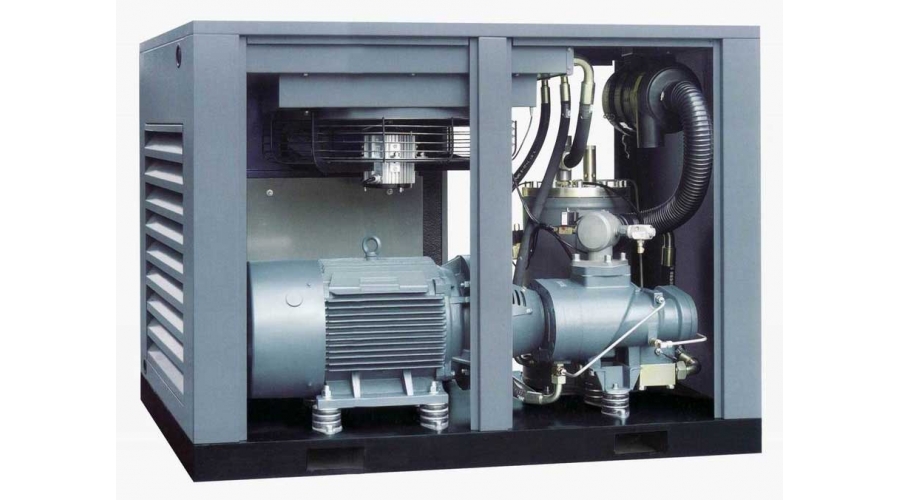

This compressor system used permanent magnet motor, compared to asynchronous induction motor pump system. Thanks to its advantages listed below, which is to be used that have variable requirements provides up to 35% energy saving and improves the compressor’s service life.

Soft Start and Longevity

Excessive current drawn during the star-delta of the electrical motor (starting current) and the mechanic loads are eliminated thanks to the soft start and stop features of this system. As a result, longevity of the motor equipment improves and maintenance costs decrease.

Economical Run and Constant Output Pressure

Standard air compressors switch to idle when the targeted pressure is achieved and switch to load when the specific low pressure is reached. When the compressor switches to idle, the electrical motor keeps working at its constant speed and does not produce compressed air hence the compressor consumes 30% power of its load run. Pumps with our permanent magnet motor, works at an optimum speed (rpm) to meet the real time air needs and provides great deal of energy savings as well as producing targeted constant output pressure.

In some cases, because we can’t rule out the possibility of long run in full load condition, we have to order motors to meet maximum demands of compressors. But in actual operation, the proportion of light load running time is quite high, it leads to a lot of energy waste. From now on, with our permanent magnet motor system, you can order a motor at rated power, and peak power can meet the full load condition. By the close loop control, the motor speed is variable automatically by your pressure condition.

Cooling Fan Motor 0.35KW, 1500RPM

In addition to the air compressor motor, in some cases, the fan cooling is required in the compressor. Volcano Electric offers one-stop solution including the intelligent cooling systems. In this case, we design the fan cooling system, with our Brushless DC motors 0.35KW, 1500RPM, air capacity 116 m3/min. conventional AC motors, when the compressor switches on ,the cooling fan is on and keeps working at its constant speed till the compressor switches off. But by using our brushless DC motor, with a temperature sensor, the cooling fan is intelligent, switch on, speed up, speed down, switch off etc is automatically controlled to maintain the ambient temperature at reasonable range. Therefore, it can save energy enormously in long terms.

Generally, as a energy saving industrial system supplier, we help customers by our one-stop service, in this compressor system, we help our customer with intelligent constant pressure system intelligent cooling fan temperature relative system.

For a professional compressor case advices, please contact us at info@volcanomotor.com. Our engineers are at your service case by case. You can try to tell us your compressor application, function requirements, efficiency etc. our permanent magnet motor pumps systems can easily replace the conventional 3 phase asynchronous electric motors with higher efficiency and intelligent.

Keywords: Intelligent compressor system, PMSM motor system, high efficiency motor system, high efficiency compressor system, constant pressure compressors, variable speed motors. Energy saving compressor system, fan cooling motor.