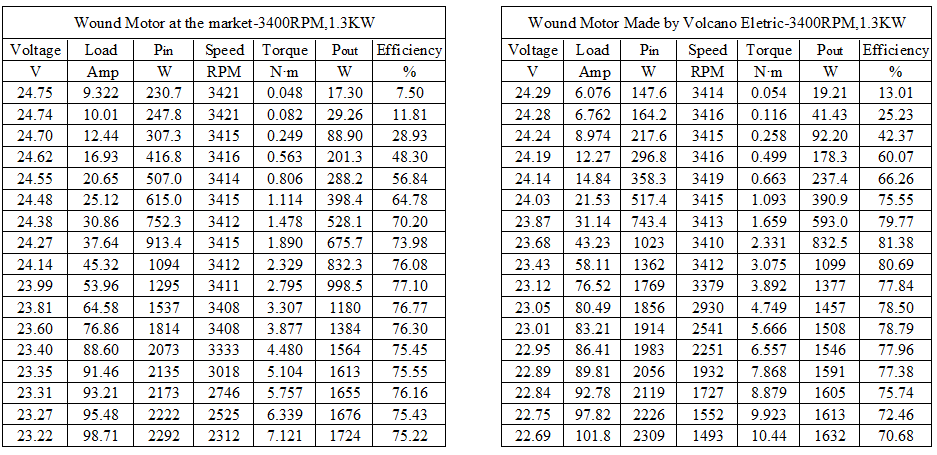

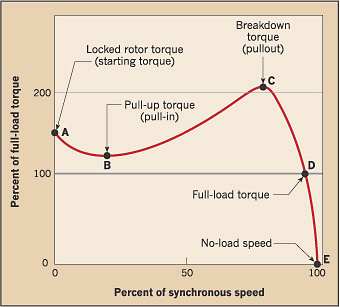

Conventional Motors in electric forklift is using wound AC motors, that we offer to most of our customers. Compared to most wound AC motor manufacturers in China, we have a professional technical team which is leaded by an Australian expert, who worked in motor research and design over 30 years. to design proper motors case by case for our customers. Thus the wound AC motors Made by Volcano Electric are more efficient and energy saving. Please refer to the performance comparison between Volcano Electric motors and Chinese Market motors.

Logistics Transportation

Electric Forklift

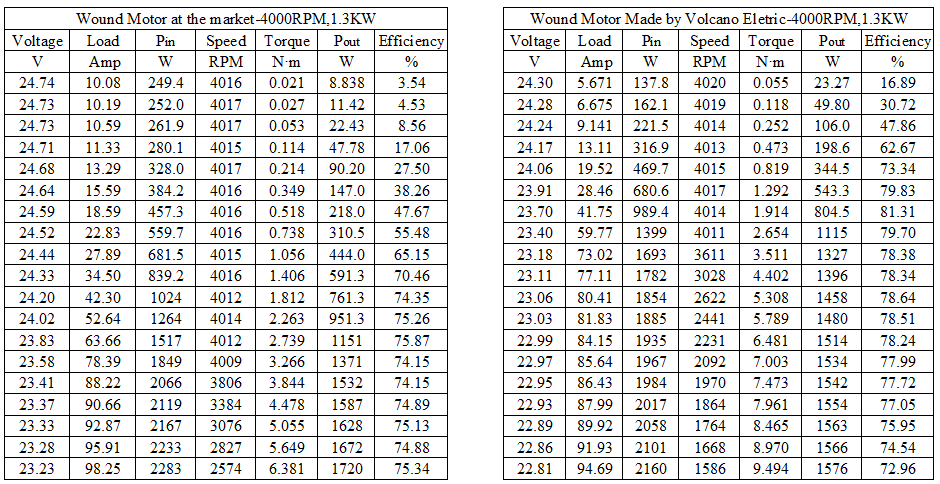

In Volcano Electric, by customers requirements, we can offer various motors for electric forklift, such as asynchronous electric motors( wound AC motors), brushed DC motors, Brushless DC motors and IPM motors( Interior Permanent Magnet Synchronous Motors)

详细描述

In Volcano Electric, by customers requirements, we can offer various motors for electric forklift, such as asynchronous electric motors( wound AC motors), brushed DC motors, Brushless DC motors and IPM motors( Interior Permanent Magnet Synchronous Motors)

Conventional Motors in electric forklift is using wound AC motors, that we offer to most of our customers. Compared to most wound AC motor manufacturers in China, we have a professional technical team which is leaded by an Australian expert, who worked in motor research and design over 30 years. to design proper motors case by case for our customers. Thus the wound AC motors Made by Volcano Electric are more efficient and energy saving. Please refer to the performance comparison between Volcano Electric motors and Chinese Market motors.

1.3KW, 3400RPM wound motor

1.3KW, 4000RPM wound motor

In additional to the conventional AC motors, our team developed Brushless DC motors in electric forklift. This IPM motor have advantages in applications which require Low speed-high torque and High speed-low torque features.

This IPM motor used in Electric vehicles, compared to AC motor system. Thanks to its advantages listed below, which is to be used that have variable requirements provides up to 35% energy saving and improves the traction system service life.

Higher efficiency for a wide range of speeds.

At constant speed both AC motor and permanent magnet DC motors can work at high efficiency. But using AC motor, when the motor speed is changed, the motor efficiency goes down sharply, while using the permanent magnet DC motors, the efficiency is higher for a wide speeds.

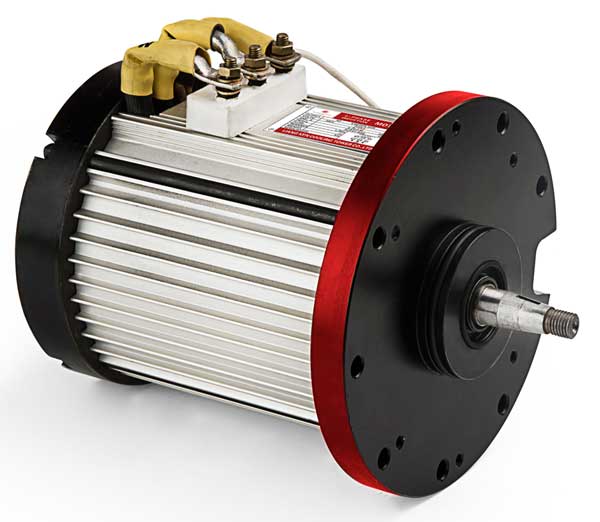

Higher Starting Torque

T-N Chart of AC motor

By the chart, Starting Torque (point A) of AC motor is quite low, as the speed up, the available torque can even a littler higher than Starting Torque. But T-N chart of a brushless DC motor is linear proportional. The Starting Torque is maximum torque of the motor, as the speed up, the torque is down to full-load torque. Thus the designed starting torque can be much higher than the full-load torque.

Ability to run at high speed-low torque / low speed-high torque.

The configuration of these motors are exactly same to conventional AC motors, basically NEMA standard or IEC standard frame motors. Thus, these IPM motors can be replaced the current motor system simply, but with much higher efficiency.

Moreover, we can produce customized motors at smaller sizes.

For a professional electric vehicle case advice, please contact us at info@volcanomotor.com. Our engineers are at your service case by case. You can try to tell us your application, function requirements, efficiency etc. our permanent magnet motor systems can easily replace the conventional 3 phaseAC electric motors with higher efficiency and intelligent.

Similar application of IPM motors: Electric forklift, Electric golf car, Electric sightseeing vehicle, Electric Logistics handing vehicle etc.

Keywords: High efficiency Traction Motor, IPM Motors, Electric forklift motors, Electric Vehicle Motors, Brushless DC Traction Motors, Permanent magnet Motors.